Workshop Lines

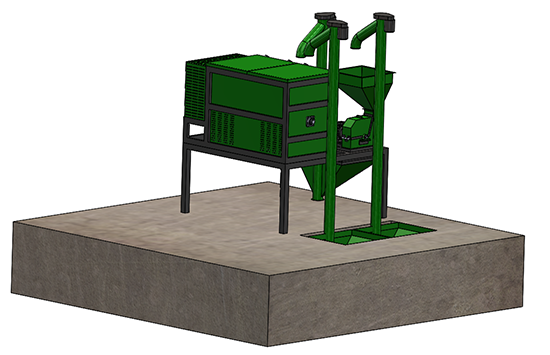

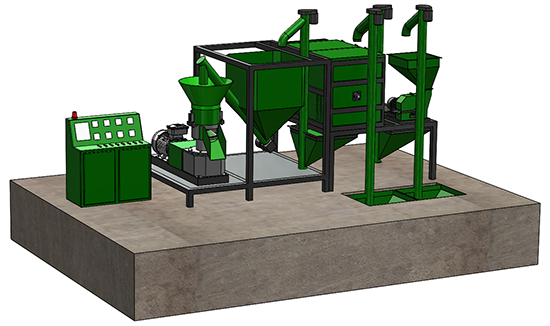

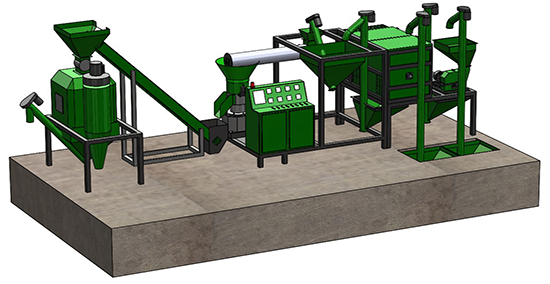

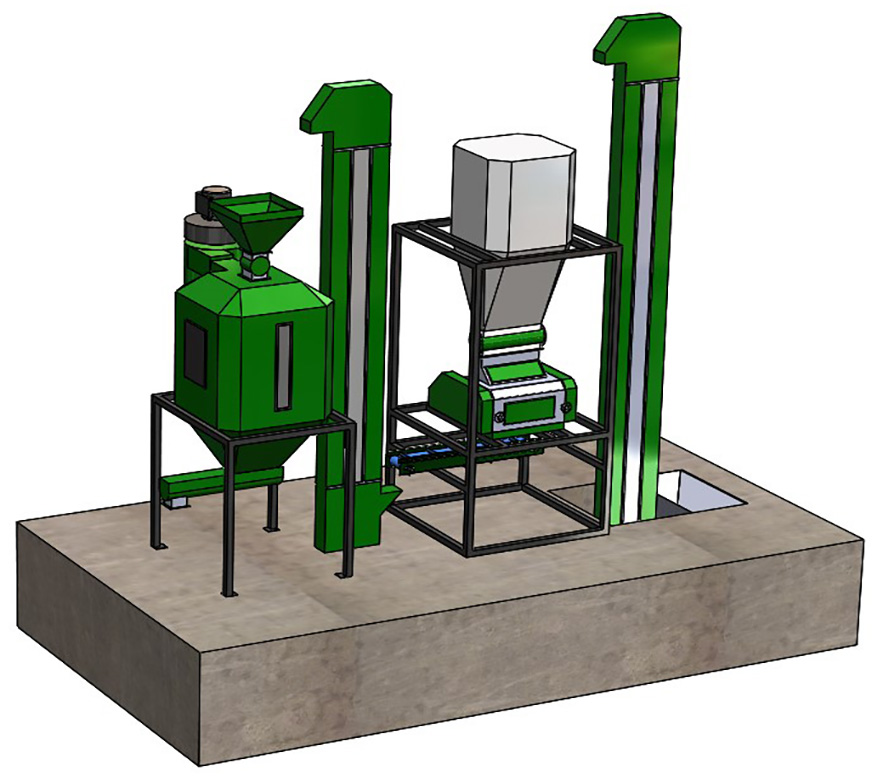

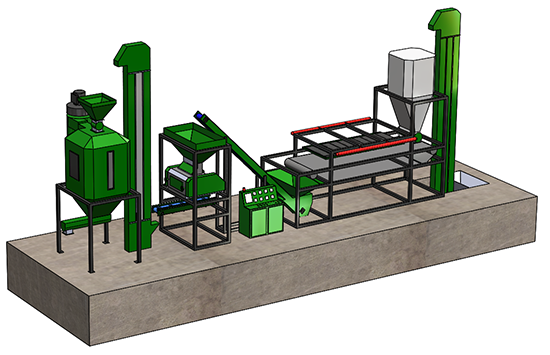

Hammer Mill and Horizontal Mixer Pack,

we are excited to introduce our Hammer Mill and Horizontal Mixer Pack, a compact and efficient solution designed specifically for the feed production industry. This pack combines two critical machines – a hammer mill for grinding raw materials and a horizontal mixer for blending ingredients – into a single, easy-to-use system.

Livestock Feed Production:

Grind and mix ingredients to produce feed for cattle, sheep, goats, and dairy animals.

Poultry Feed Production:

Process ingredients for broilers, layers, and breeders.

Ensures uniform mixing of vitamins, minerals, and other additives for high-quality poultry feed.

Aquaculture Feed Production:

Grind and blend ingredients for fish, shrimp, and other aquatic species.

Perfect for creating specialized feed formulations for different stages of aquatic life.

Small Farms and Startups:

Perfect for small-scale operations looking to produce their own feed on-site.

Reduces dependency on commercial feed suppliers and lowers costs.